Acar leads NSF-funded research that goes against the grain

January 11, 2022

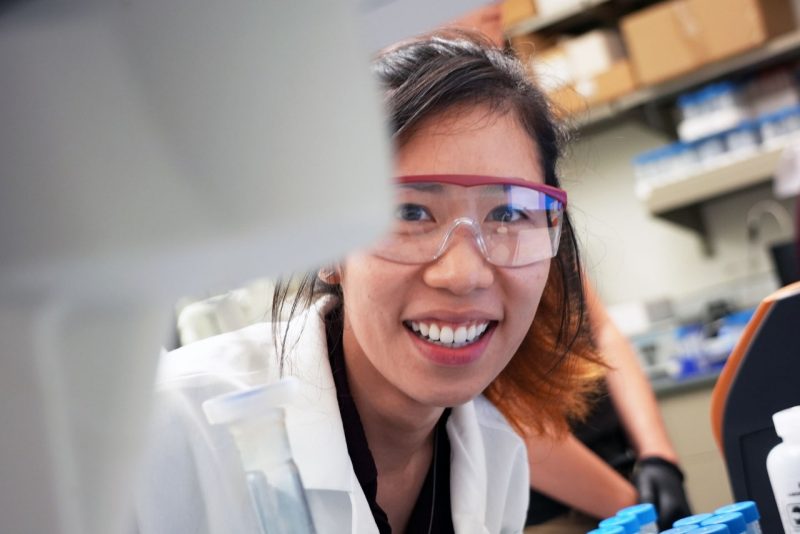

Pinar Acar, assistant professor in Mechanical Engineering, received a National Science Foundation award totaling $651,452 over three years, aimed at improving the strength and performance of titanium microstructures.

When titanium is shaped, it is heated and then cools. As that cooling occurs, the microstructure of the metal will settle with sections of the material clustering together. Between these clusters are formed a grain, not unlike the grain of a wooden board, with lines of microscopic gap running between the sections. Where these gaps occur, there also exists the possibility of less strength. (To again use an example from a wooden board: driving a nail into the grain of a wooden board may cause it to split, and that split generally travels along the grain.)

To make the metal stronger, the general approach is to keep the grain from occurring, restricting the microstructure into more interlaced, smaller grain clusters that retain their strength.

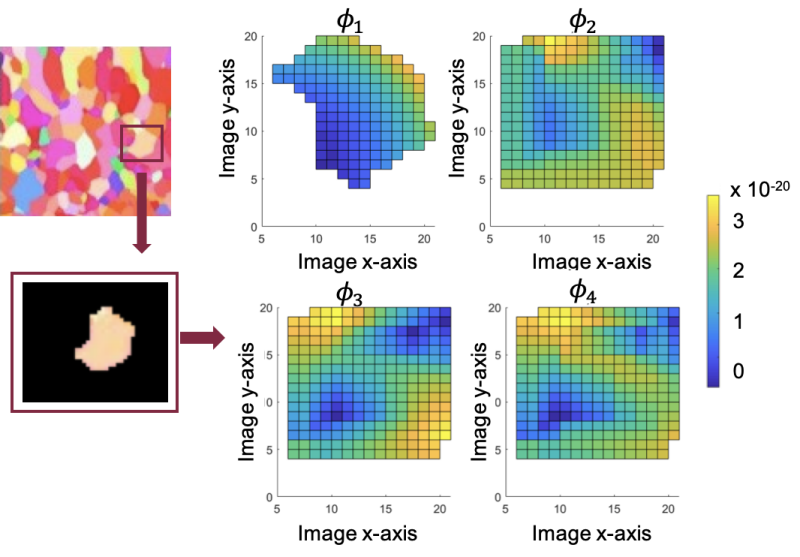

Acar and her team will take the approach of using artificial intelligence and machine learning, programming observational tools that measure these gaps and determining the best design for better strength of the material at the microscale.

The work will not be completely idea-based. Once a mathematical approach is established, the group will bring the concepts to life by taking manufacturing constraints into consideration. They will also keep a close eye on cost considerations for an eventual handoff to the larger world of academia and industry.

Work from the grant was presented at the annual meeting of the American Institute of Aeronautics and Astronautics (AIAA), January 3-7, 2022. The paper, “New Methodologies for Grain Boundary Detection in EBSD Data of Microstructures,” included the group’s exploration of the formation of grains in titanium alloys. That project will be brought into the larger effort, using their findings for grain identification to pinpont the best methods for engineering the microstructure with less weaknesses in those grain lines.