PEP in a pizza box: the value of take-home labs

Take-home labs bring a new dimension to hands-on learning

February 24, 2021

Two Virginia Tech professors in mechanical engineering have led the way in expanding hands-on learning during a time when in-person experiences have been significantly decreased.

When classes went online following the global COVID-19 pandemic, most hands-on learning was an unfortunate casualty. Many instructors substituted prerecorded videos or livestreamed demonstrations in their place. While the use of online resources bridged the gap in many ways, there is still no substitute for the rich experience of learning by doing. Into this difficult time, professors Tom Diller and Al Wicks brought a viable option: take-home labs.

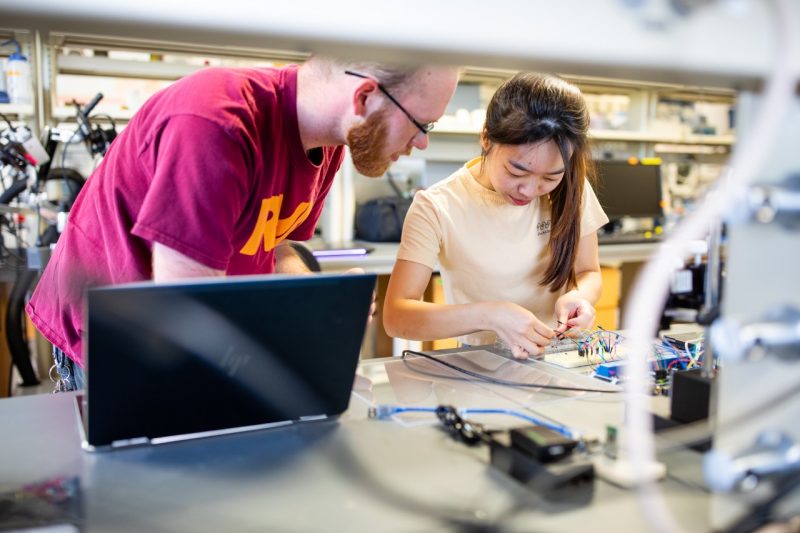

Diller’s teaching centers on heat transfer, the study of how energy moves between and through materials. His research focuses on measuring heat flux to and from surfaces. Since 2017, he has worked with Wicks to develop a kit with temperature and heat flux sensors that connect through a micro-controller to a student’s laptop. Material samples and a small heater are also included, allowing students to take readings on wood, aluminum, cloth, walls and even their own skin to better understand the basic concepts of heat transfer. As energy transfers between materials in the form of heat, the data is recorded through the micro-computer which connects to the laptop via USB, showing on a visual display. The kits are called personal engineering platforms, or PEPs.

The kits had already proven to be popular among students, increasing engagement and course performance, according to Diller. At the beginning of 2020, as college campuses closed around the country, all 350 juniors in the required heat transfer course were given a kit on loan for the semester.

“The timing was fortunate,” said Dillard.

With the advent of COVID-19 stay-at-home orders in March, all of Diller and Wicks’ juniors continued with the hands-on workshops, even while the course lectures were required to go online.

Because of their success in 2020, the mechanical engineering department moved to expand the use of the lab kits to all students in the junior laboratory course. Five experiments were converted to the new system for spring 2021. This required additional sensors and actuators for the new experiments.

Getting ready for delivery

Working with graduate students to assemble and package the new kits over the winter holiday break, they found readily available packaging that was the right size and could be affordably purchased in large quantities: pizza boxes. The boxes the group chose could accommodate a small personal pie, are sturdy, and easily fit into a backpack.

With the gear in the boxes, the team could set up in a large, open space and arrange times for students to safely pick up their lab kits. 20 kits were mailed to students outside the Blacksburg area.

While the sheer ability to conduct lab research at home is a revelation in itself, there are unique additional benefits to working this way. Senior Travis Bowman was a student in Diller’s class, and appreciated the ability to work at his own place.

“Take-home labs eliminate the chaos and stress of trying to make sure that your lab worked and that your data makes sense in the hour-long lab period,” Bowman said. “It gives the students valuable time to tinker with the equipment and sensors, so they can really understand what is happening with the readings they see and why, rather than trying to quickly get through a set of instructions before their time is up.”

Senior Caleb Adams also appreciated this increased flexibility as well.

“The kits were easy to use and apply to all sorts of experiments, and the ability to do them on my own time allowed me to take my time and explore different possible setups that produced different results,” Adams said. “The kits helped make heat transfer intuitive by letting me try different combinations of things and see what results they had. In a typical lab environment, I would not have the time to test different theories and hypotheses for my own curiosity, and these kits allowed us to do just that.”

Diller is working with other faculty in mechanical engineering to expand the idea of portable labs to other courses. Colleague Steve Southward has developed a virtual version of his controls lab, an idea that Texas Instruments highlighted in an invited webinar. The department is exploring further expansion to other classes for at-home studying of mechanical strain sensing, proportional–integral–derivative controllers, inertial sensing, GPS sensing, ultrasound sensing, radar, pressure sensing, and wireless communication.